Total Productive Maintenance (TPM)?

Total Productive Maintenance (TPM)?

TPM is a maintenance management strategy that focuses on increasing equipment effectiveness, decreasing downtime, and improving overall productivity and quality. TPM is a comprehensive and proactive maintenance method that engages all employees in the process of continuous improvement, from operators to supervisors. TPM aims for zero breakdowns, zero faults, and zero accidents by ensuring that equipment is always available, dependable, and capable of producing high-quality products. In this article, we will take a look at the key principles, benefits, and implementation steps of TPM, as well as the tools and strategies used to achieve TPM goals.

History of Total Productive Maintenance (TPM)

Total Productive Maintenance (TPM) originated in Japan in the 1950s as a maintenance plan to support the country’s industrial industry. TPM arose in response to the compelling need for enhanced asset management as Japanese industry sought to recover following World War II. TPM was originally called “productive maintenance,” and it aimed to improve the efficiency and effectiveness of manufacturing machinery.

Total Productive Maintenance (TPM) originated in Japan in the 1950s as a maintenance plan to support the country’s industrial industry. TPM arose in response to the compelling need for enhanced asset management as Japanese industry sought to recover following World War II. TPM was originally called “productive maintenance,” and it aimed to improve the efficiency and effectiveness of manufacturing machinery.

TPM gained traction in the 1960s as Japanese manufacturing firms embraced quality management and continuous improvement principles. During this time, TPM began to combine the concepts of “autonomous maintenance” and “operator-driven maintenance,” which aimed to involve all employees in repairing their equipment rather than depending exclusively on maintenance personnel.

The PM Award was established in 1971 by the Japanese Institute of Plant Maintenance (JIPM) to honor companies that have made significant breakthroughs in production management. Nippon Denso, a Japanese automobile parts manufacturer, was the first to get this award for implementing a thorough TPM program. Later, the JIPM expanded on the TPM concept, adding eight pillars that covered all aspects of manufacturing, such as safety, quality, and cost reduction.

TPM has since become a widely used approach to maintenance management, with many firms worldwide implementing its concepts into their maintenance operations. TPM has expanded beyond its basic focus on manufacturing machinery to include all forms of physical assets, including equipment, buildings, and infrastructure. As new technologies and business processes are continually being developed, it continues to evolve and adapt, with the key principles of TPM staying focused on improving assets.

The 5 Essential Building Blocks of Total Productive Maintenance

TPM, a manufacturing industry concept, has evolved beyond preventive maintenance to include productive maintenance, maintenance prevention, and reliability engineering. This strategy, which involves the workforce behind the machinery, strives to improve overall equipment efficacy.

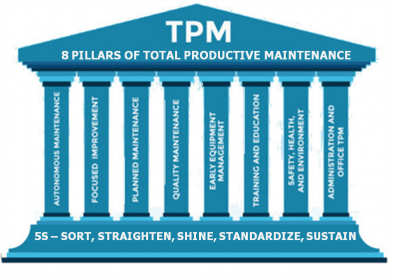

The traditional TPM model is based on the 5S methodology, consisting of a 5S foundation (Sort, Straighten, Shine, Standardize, and Sustain) and eight supporting pillars, with the goal of achieving an organized and efficient workplace through the following sequence.

Step 1 – Sort: Go through all tools, materials, and equipment in the working area and remove anything unnecessary.

Step 2 – Straighten: Organize the necessary items in a way that promotes efficient and easy retrieval, and reduces unnecessary travel between working groups and locations.

Step 3 – Shine: Clean and maintain the work area and equipment to keep them in good working condition and minimize the risk of defects.

Step 4 – Standardize: Establish standards for maintaining the previous three S’s and provide training and resources to ensure everyone adheres to them.

Step 5 – Sustain: Continuously maintain and improve the previous four S’s to achieve a culture of cleanliness, efficiency, and quality in the workplace.

These five core elements, in conjunction with the Eight Pillars of Total Productive Maintenance, are utilized to establish a comprehensive maintenance program.

8 Pillars of Total Productive Maintenance

These 8 pillars increase overall equipment reliability and performance:

- Autonomous Maintenance: Autonomous maintenance involves teaching equipment operators how to perform regular maintenance tasks on their machines, ensuring that employees take personal responsibility for the upkeep of their equipment and proactively identify any potential issues.

- Focused Improvement: Small teams work collaboratively using a cross-functional approach to continuously improve processes and workflows, resolving issues through focused and continuous improvement.

- Planned Maintenance: Preventive maintenance is scheduling routine maintenance based on machine performance and failure-rate data, aiming to prevent unplanned downtime and eliminate breakdowns.

- Early Equipment Management: Early equipment management involves leveraging the practical knowledge and experience of machine operators in the design of new equipment, making maintenance easier and enabling planned performance levels to be achieved soon after the adoption of new equipment.

- Quality Maintenance: Quality maintenance helps to improve overall production quality and eliminate defects by identifying the root causes of equipment failures and recurring issues.

- Training and Education: The training and education element emphasizes continuous learning and development to ensure maintenance tasks are executed effectively at all times, with all relevant parties receiving sufficient training on the goals and standards of TPM.

- Office TPM: Beyond production operations, TPM also helps to improve administrative operations through the office TPM element, which simplifies procurement, scheduling, and order processing to ensure that tools and materials are always available when needed.

- Safety, Health, Environment (SHE): TPM places the safety, health, and environment of employees at the forefront of its operations, ensuring a safe working environment at all times.

Benefits of Total Productive Maintenance

Improved Equipment Effectiveness: TPM helps to increase equipment performance by minimizing downtime, enhancing dependability, and maximizing overall equipment effectiveness (OEE). TPM trains equipment operators to do routine maintenance, preventing equipment malfunctions and decreasing downtime.

Improved Quality: TPM promotes the early discovery and resolution of quality concerns, which helps to limit the occurrence of defective products. TPM assists in the elimination of manufacturing problems by focusing on quality and preventative maintenance.

Reduced Costs: TPM can help to reduce maintenance and repair costs by minimizing equipment breakdowns, prolonging the lifespan of equipment, and reducing the need for costly repairs.

Increased Safety: TPM promotes safety by ensuring that equipment is kept in good operating order, lowering the risk of accidents and injuries.

Employee Engagement: TPM emphasizes the importance of including employees in the maintenance process in order to increase their sense of ownership and responsibility for the equipment they use. As a result, employee engagement, job satisfaction, and motivation improve.

Improved Communication: TPM requires effective communication between different departments, creating a culture of collaboration and cooperation. This can help to improve overall organizational communication and lead to better decision-making.

Continuous improvement: TPM is a continuous improvement process, which can help organizations stay competitive and adapt to changing market conditions over time.

The Importance of a TPM Program: How to Get Started

TPM (Total Productive Maintenance) programs should be implemented in every organization that relies on machinery and equipment to operate. By minimizing equipment downtime, extending equipment lifespan, and identifying and eliminating production inefficiencies, a well-executed TPM program can result in significant increases in productivity, efficiency, and cost savings. A TPM program can also help to enhance the safety of the workplace and the quality of products produced by an organization. A TPM program may promote a culture of continuous improvement and a sense of ownership and responsibility for the equipment and processes involved in the production of goods and services by involving everyone in the organization, from management to front-line employees. Overall, the importance of implementing a TPM program cannot be overstated, as it can lead to long-term success, profitability, and a competitive advantage in the marketplace

The seven steps of implementing a Total Productive Maintenance (TPM) program are:

Preparation: This involves entails establishing the program’s objectives, reviewing the present state of the equipment, and identifying opportunities for improvement.

Initial Assessment: This process entails gathering data on the performance of the equipment, identifying waste sources, and prioritizing the equipment to be improved.

Development of Standards: Standard operating procedures and equipment maintenance standards are developed during this step.

Education and Training: This step entails educating and training operators and maintenance workers in order to increase their skills and knowledge.

Implementation: This step involves implementing the TPM program on the selected equipment, establishing monitoring and evaluation systems, and starting to collect data on the program’s performance.

Continuous Improvement: This step entails analyzing the program’s performance on a regular basis, identifying areas for improvement, and adopting corrective actions.

Consolidation: Finally, the successful TPM program is incorporated into the organization’s culture and processes, best practices are shared, and the program’s performance is continuously improved.

Final Thoughts

While TPM may not be the best solution for every organization, many of the principles it provides can help improve the efficiency and effectiveness of equipment maintenance. Following the seven steps of implementing a Total Productive Maintenance program, organizations can identify areas for improvement, set standards, and procedures, train employees, and continuously monitor and improve their equipment maintenance processes. Even if an organization does not fully embrace TPM, applying some of its concepts can assist to minimize downtime, improve equipment reliability, and increase productivity. Ultimately, the objective is to create a culture of continuous improvement and operational excellence, and TPM principles can be a significant tool in achieving this goal.